Ankrit Technologies GmbH

Kirchbergstr. 23

86157 Augsburg

Germany

Tel: +49 (0)821-47866780

[email protected]

Commercial registration

Headquarters: Augsburg

Managing director: Julia Sailer

Commercial register Augsburg: HRB 26664

VAT no.: DE 281389180

We are pleased about your visit to our website and your interest in our products. All information that you transmit to us is only used for individual customer service purposes. The information is treated confidentially and not made available to other companies under any circumstances.

We point out that the contributions on these pages are only intended for information purposes. We cannot guarantee the completeness, accuracy and topicality of the content. The publication or dissemination of any content requires the express consent from Ankrit Technologies GmbH.

Ankrit Technologies GmbH excludes any liability for damage arising directly or indirectly from the use of this website, as far as it is not caused through intent or gross negligence by Ankrit Technologies GmbH. Despite careful verification of the contents we accept no liability for content of external links. The content of the linked sites is the sole responsibility of their respective operators.

© Copyright 2015 Ankrit Technologies GmbH, Diedorf, Germany. All rights reserved. Text, images, graphics and videos as well as their placement on the website are subject to copyright protection as well as other protection rights. The content of this website must not be copied, disseminated, changed or made available to third parties for commercial purposes.

Ankrit Technologies has established a promising niche for itself with the manufacturing of carbide electrodes.

Our electrodes allow electrical discharge machining of high precision boreholes.

We currently offer tungsten electrodes with a diameter range from 70 μm to 300 μm in steps of 1 μm. Lengths between 100 mm and 500 mm are available.

The quality of the electrodes is defined by

» the constant diameter with a tolerance range of only 0.5 μm

» a high rigidity due to the material properties of tungsten

» precise roundness

» high precision of the cut edges

» galvanically polished surfaces

Tungsten is the ideal electrode material for electrical discharge machining. With a melting point of 3,422 °C and an elastic modulus which is twice as high as that of steel, this material has an extremely high useful life. This decreases wear on the electrode which has to be replaced less often than with conventional alloys.

Micro tungsten electrodes offer a wide range of applications: Fields such as micro mechanics, mechatronics and medical technology benefit from the impressive possibilities of micro EDM for the machining of tools, machine parts, surgical needles or implants and boreholes with diameters from 0.06 mm without burrs and entry deformation.

Series machining of injection holes in diesel injection nozzles can be carried out with great efficiency using tungsten electrodes. The very narrow diameter tolerances of the electrodes in the sub micrometre range play a crucial role for complying with emission limits.

Micro EDM (electrical discharge machining) refers to spark erosive material removal. It is a thermal ablating process where current discharges take place between the tool and the workpiece electrode within a gas chamber. EDM is based on a thermal function principle which is virtually free from processing forces, allowing machining irrespective of hardness and strength of the material. This makes it an established process for the manufacturing of precision components.

Using a simple cylindrical rod electrode, which is usually made of tungsten, carbide or silver, precision holes in the micro and macro range can be manufactured. The term Micro EDM is then used when the geometry to be produced is smaller than 500 microns. The high-precision electrodes have extremely small diameters down to 50 microns (0.05 mm).

As an engineering office we have been working with very special and often unique challenges for many years. The central concept for the development of special purpose machines can be a complete “turnkey” solution or the support for our customer teams with challenging individual problems.

We accompany our customers from the initial idea to the finished product, dividing the project into many individual tasks across all project phases.

The task of our project management is to supply the required scope of products and services within an adequate time period and within the defined budget. We take a targeted approach, ensuring that the defined milestones are achieved with the planned resources. Transparency and traceability are special priorities for us, particularly if changes to the plans are requested or required.

For all our projects, we apply the respective European directives, particularly the Machinery Directive 2006/42/EC. A safety concept and a risk analysis allow the required manufacturer’s declaration of conformity with CE marking.

Although our customers come from different industries, our projects have a common objective: strengthening the competitive position through optimisation of production and quality control with innovative special purpose machines and devices. Achieving this common objective requires respectful cooperation with customers and a mutual exchange of experiences and know-how. Trust and confidentiality are a matter of course in this.

The ISOMED product range of video isolation amplifiers has been established in the market in the field of patient safety for many years. In 2011, Ankrit Technologies took over the production and sales rights and has been looking after the extensive customer base since then. We supply specialist retailers, IT system houses, manufacturers of diagnostic devices, hospitals and GP practices who use their medical devices responsibly with our isolation amplifiers.

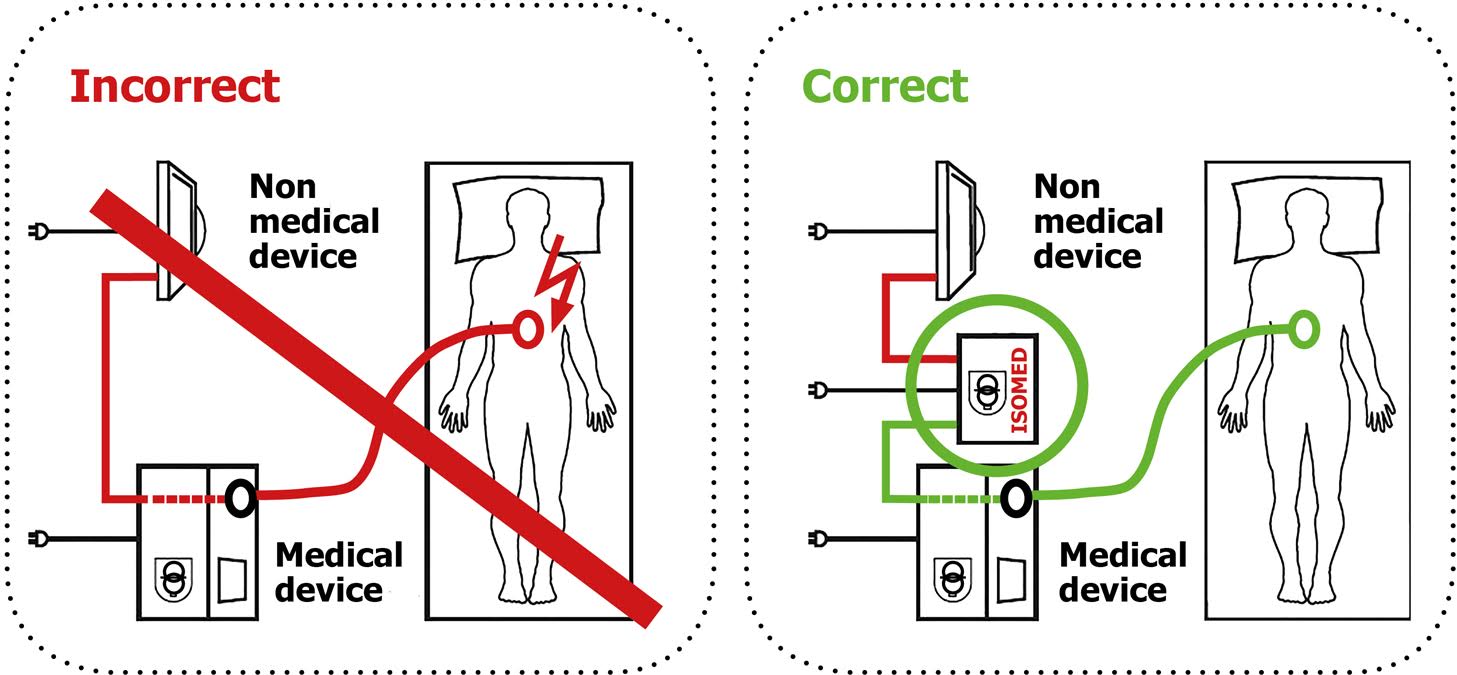

Connecting medical devices such as ultrasound or endoscopy devices to printers, monitors or storage media which are not subject to the stringent standards for medical devices voids their operating licence.

The Medical Devices Directive and the German Medical Device Operating Ordinance (MPBetreibV) stipulate a galvanic isolation for this in order to protect patients and operators against fatal leakage currents caused by defective periphery devices.

The European standard EN 60601-1 for medical electrical devices additionally requires an approved safety transformer and the required creepage distance of 8 mm for a dielectric strength of 4,000 V between power supply and inputs/outputs. This is the only way of ensuring safe operation of the medical devices together with the corresponding non-medical devices.

The ISOMED is a class I medical device and complies with the requirements of the directive 93/42/EEC and EN 60601-1. It is consequently a cost-effective way of implementing the legal requirements.

Since our foundation in 2011, three very different business areas have been linked by this central concept: engineering at the highest level. This applies to the area of medical technology as well as to special purpose machines and electrode manufacturing.

We have ideas and patents, we develop for ourselves and for our customers, we build functional models and prototypes which we then develop until they are ready for volume production. Some of the resulting products are then manufactured and sold by us, for example our successful ISOMED product range.

We are also in demand as consultants and development partners for large technology leaders who make use of our expertise for specific projects.

Many new products from Ankrit provide our customers with optimisation potentials for production and quality control, strengthening their competitive position.

This concept has proven successful for us and for our customers, allowing the company to grow.

Our move from Augsburg to Diedorf in 2015 provided a new home for the medical technology sector as well as a lot of space for mechanical engineering.

Welcome to Ankrit Technologies GmbH!

Julia Sailer and Fritz Pauker are the pillars of our company, an ideal combination of business know-how and inventive engineering with plenty of support from their competent team. Some of the employees at Ankrit Technologies have been accompanying the company founders for many years, excelling with specialist knowledge, experience, quality awareness and entrepreneurial spirit. Young employees are increasingly being integrated.

The tasks, especially for special purpose machines, often require expert knowledge from different technical fields which cannot be covered by the core team. For this expert knowledge, we have established a network of highly competent engineers over the course of the years. This allows us to put together a suitable team of experts for each task and the respective time period. We take on project management and project responsibility as a general contractor.

In the field of mechanical engineering, we apply the respective European directives, particularly the Machinery Directive 2006/42/EC. A safety concept and a risk analysis allow the required manufacturer’s declaration of conformity with CE marking.

The quality management system of Ankrit Technologies GmbH is certified to EN ISO 9001:2015.

Ankrit Technologies is registered with the German national register for waste electric equipment (ear Foundation) to support environmental management.

Our WEEE reg. no.: DE 64007326

Our ISOMED Version II products are class I medical devices compliant with the requirements of the directive 93/42/EEC and the requirements of the directive 2011/65/EU (RoHS).

The devices are manufactured in line with EN 60601-1 (3rd edition).